Companies can gauge their level of Industry 4.0 adoption by judging whether they have smart products, factories, and operations in place. In other words, are products and company assets connected and communicating with higher-level systems? When companies operate smart factories, they utilize automated and connected manufacturing processes.

Smart operations digitally model processes and products while controlling them virtually through algorithms. With smart operations, companies can control, monitor, and adjust processes in real-time. Product planning systems and supply chain management are examples of smart operations that integrate the physical and virtual.

Data Virtualization and Visualization

To reach Industry 4.0 maturity, companies need to embrace data-driven services. Organizations must gather and analyze the data generated by connected devices to make decisions about how to improve products, services, and operations. For example, manufacturers can use data analytics to improve supply chain logistics and inventory management.

The data generated by sensors can be mined for deep insights using advanced analytics. These insights help to optimize and automate operations and ensure that tracking and preventative maintenance is being carried out on valuable company assets.

The right network technology is needed to visualize data at the edge. Some connected devices may have compute capabilities at the edge, and others may need to be connected to a centralized system. More data needs to be pushed from the edge to the cloud. INS can help companies design and develop technology for data visualization.

Barriers to Industry 4.0 Adoption

Many Industrial companies face challenges in adopting Industry 4.0 because they rely on legacy networking hardware and communications technologies, as well as outdated protocols that create security and connectivity problems.

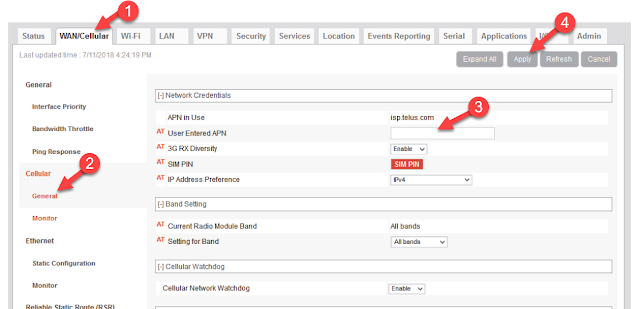

For example, companies in the Industrial space may not realize they can use cellular technology to achieve connectivity. Today, everything is remote and wireless, so companies need to be willing to refresh their network hardware to support wireless connectivity.

A major barrier to making updates is that many companies may not understand their budgetary needs enough to plan for investments in a technology refresh. Some organizations don’t even have a refresh cycle in place.

Without a budget and plan for technology refresh cycles, Industrial companies can’t achieve Industry 4.0 maturity. Modern networking technology, such as updated switches and routers, is needed to connect the sensors on IoT devices to the internet and the cloud. Other innovations, such as process automation, must be supported by up-to-date networking technology. Companies also need wireless networking for real-time closed-loop process control and non-real-time process and asset monitoring.

At INS, we help our customers overcome these barriers by giving them access to the latest networking solutions from leading technology companies, such as

Cisco.

Raising Your Level of Industry 4.0 Maturity

Partnering with the right technology company will help you progress on your journey to Industry 4.0. You need to work with a partner with expertise in operational technology and Industrial IoT.

Industrial Networking Solutions (INS) specializes in designing, deploying, and supporting operational technology. We have delivered hundreds of Operational Technology/Industrial IoT (OT/IIoT) networks. As a Cisco partner, we provide our customers with leading wireless networking solutions to support data visualization and automation.

To learn more about how to implement modern Industrial networking solutions,